Elevating Workstation (EWS) – Ergonomic ULD Handling

Streamline Build & Break Operations with Optimal Ergonomics

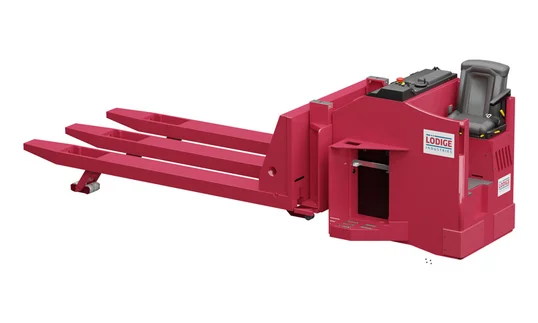

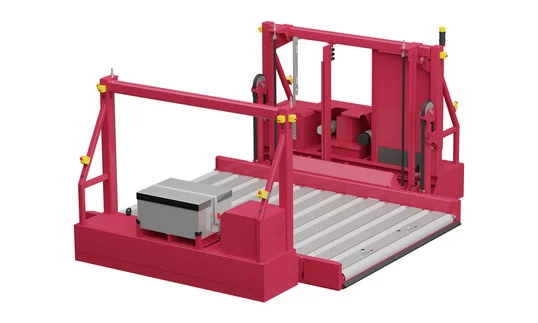

Enhance safety, ergonomics, and productivity in your cargo handling process. The Elevating Workstation (EWS) from Lödige Industries ensures optimal working heights for loading and unloading ULDs, significantly reducing strain and improving efficiency in build & break areas.

Flexible, Ergonomic, and Efficient Cargo Handling

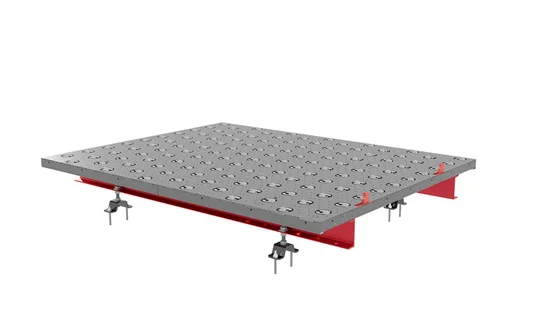

The Lödige Elevating Workstation is designed for ergonomic handling of main deck ULDs. Featuring powered roller decks mounted on robust scissor lift assemblies, the EWS enables adjustable heights for comfortable cargo operations. Integrated steel safety skirts and precise lifting controls ensure maximum operational safety and efficiency.

Benefits of Lödige’s Elevating Workstation

Designed for innovative air cargo terminals, our solutions provide measurable benefits by improving efficiency, ensuring safety and supporting seamless process integration.

Proven Features & Options

The Elevating Workstation comes with a set of proven features and optional enhancements. These ensure reliable performance in daily cargo operations and allow flexible adaptation to specific terminal layouts and process requirements.

Features / Options

- 10 ft WEP & NEP, 20 ft NEP

- Platform EWS for 10ft ULD Support Pallet

- Integrated scale

- Various types of ram protection

- Drive-over possibility

Technical Data

Description | 10ft NEP | 10ft WEP | 20ft NEP |

|---|---|---|---|

| Capacity | 6,800 kg | 6,800 kg | 13,600 kg |

| Length | 3,600 mm | 3,000 mm | 7,200 mm |

| Width | 2,700 mm | 3,470 mm | 2,700 mm |

| Conveying speed | 18 m/min | ||

| Elevation in top position | + 203 / + 508 mm | ||

| Elevation in lowest position | - 1,400 mm | ||

| Lifting stroke | 1,908 mm | ||

| Lifting speed | 0.05 m/s | ||

Automation Degree

The degree of automation of an EWS depends largely on integration with upstream processes and digital systems. While personnel are still required for build and break activities, automation supports manual work and improves efficiency in handling and positioning. Depending on the configuration, automation can include the feeding of ULDs and the digital processing of information – from simple manual feeding and scanning to fully automated transfer, where ULDs are already registered and processed in the Cargo Professional Suite. Choose the automation level that matches your operational needs.

Tools & Downloads

-

Luchtvracht terminaluitrusting

Brochure (engels)

Related Products

Discover Equipment for ULD Handling

Explore related products that support every step of ULD handling in your terminal. From acceptance to storage and onward transfer, these solutions ensure efficiency, safety and smooth integration into your cargo flow.

From Landside to Airside – Explore the Processes

Navigate through the key steps of air cargo handling and explore how our solutions support each process.

Frequently Asked Questions (FAQs)

The EWS supports loads up to 13,600 kg for 20ft configurations and up to 6,800 kg for 10ft configurations.

The workstation can be adjusted from 508 mm to 1400 mm above the floor, offering ergonomic working positions.

Yes, it is designed for 5ft, 10ft, 15 ft and 20ft ULDs, adapting flexibly to different cargo handling scenarios.

Yes, integrated safety skirts, hydraulic safety valves, and controlled lifting ensure secure and safe operation.

Yes, it fully complies with IATA guidelines for safe and efficient cargo handling.

Yes, the workstation features corrosion-resistant finishes suitable for outdoor environments.

Maintenance is straightforward, as all key components are easily accessible, significantly reducing downtime. A maintenance pit is also provided.

Yes, it seamlessly integrates into automated and semi-automated terminal setups and connects with Cargo Professional Suite.

Yes, Lödige can customise workstations to meet specific operational needs or constraints.

It typically requires a standard industrial power supply, suitable for terminal environments.

Yes, it can be configured specifically to accommodate temperature-sensitive or special handling cargo.

Yes, it includes emergency stop mechanisms and manual overrides for enhanced operational safety.