Luchtzijdige interface voor luchtvrachtterminals

Betrouwbare overdracht van ULD's naar het platform

De airside interface is de link tussen de vrachtterminal en het platform. Uitgaande ULD's moeten het vliegtuig op tijd bereiken, terwijl inkomende eenheden snel en veilig moeten worden geaccepteerd. Nauwkeurigheid, coördinatie en IATA-conforme afhandeling zijn essentieel voor het handhaven van vluchtschema's. De oplossingen van Lödige maken naadloze transfers in beide richtingen mogelijk, van handmatige verwerking tot volledige automatisering.

Het interfaceproces aan de luchtzijde

Uitgaande ULD's worden toegewezen aan hun respectieve vluchten en vanuit de terminal vrijgegeven aan de dolly-docks. Ondersteund door geïntegreerde software kan het scannen en registreren automatisch worden uitgevoerd om een nauwkeurige timing en positionering te garanderen. Bij inkomende zendingen worden ULD's die van het vliegtuig komen bij dezelfde dokken ontvangen, geregistreerd en naar afbraak- of opslagruimten geleid. Optionele controles zoals schade-inspectie of contourcontrole kunnen naadloos in het proces worden geïntegreerd.

In de airside interface combineren we vier sterke punten: producten, software, systeemplanning en service. Samen zorgen ze voor naadloze ULD-transfers van dollydocks naar de terminal en terug - voor operationele efficiëntie, veiligheid en prestaties op tijd.

Voordelen van Lödige's oplossingen voor luchtzijdige interfaces

Onze procesoplossingen zijn gericht op operationele workflows en creëren tastbare voordelen door afhandelingsstappen te stroomlijnen, doorlooptijden te verkorten en een soepele coördinatie mogelijk te maken in alle zones van de luchtvrachtterminal.

Flexibele automatisering voor interfaces aan airside

Van handmatige acceptatie naar volledig geïntegreerde overdracht

Airside Interface systemen kunnen op verschillende automatiseringsniveaus worden geïmplementeerd - van handmatige palletverplaatsing tot volledig geautomatiseerde ULD routering. Hierdoor kunnen luchtvrachtterminals hun activiteiten aanpassen aan het volume, de beperkte ruimte en de investeringsprioriteiten.

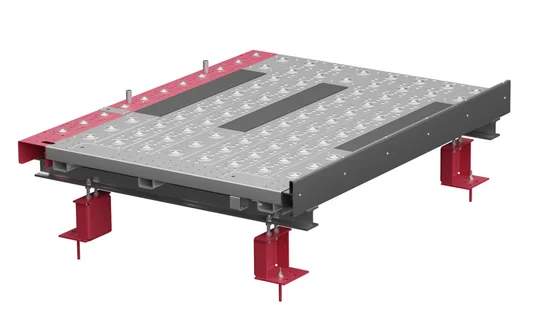

Volledig geautomatiseerd

Volautomatische systemen zorgen voor een maximale doorvoer en procesbetrouwbaarheid, zelfs tijdens piektijden of personeelstekorten. Ze worden gebruikt in terminals met hoge volumes, strikte prestatiedoelen en beperkte ruimte. Het systeem plant en triggert automatisch alle jobs, beheert de communicatie met de apparatuur en zorgt ervoor dat de SLA volledig wordt nageleefd en dat de gegevens worden bijgehouden. De functies omvatten de interface tussen terminal en platform en de automatische overdracht van en naar dollies.

Typische apparatuur | Software-onderdelen |

| - Automatisch dolly dock | Cargo Professional Suite (TMS) met Cargo Control en Cargo Direct Modules: - Airside Management - ULD Control System |

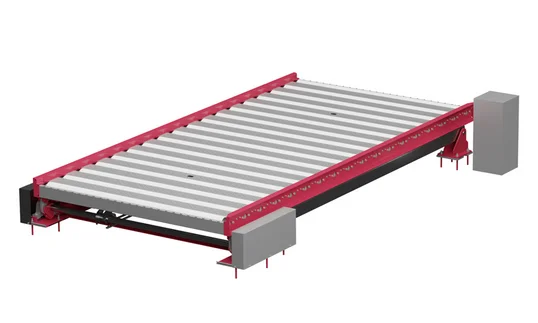

Semi-automatisch en mobiel

Semi-automatische systemen combineren mobiele en stationaire apparatuur om de verwerking bij de interface te stroomlijnen. Op batterijen werkende Cargo Pallet Movers en FlexLoaders verminderen de handmatige inspanning en verhogen de snelheid en veiligheid van het proces. De functies omvatten de interface tussen terminal en platform en semi-automatische overdracht van en naar dollies.

Typische apparatuur | Software-onderdelen |

| - Draaitafel (met haaks dek) - Roldek - FlexLoader - Truck Dock - Kanteldek - ULD-deurherkenning - ULD-identificatie - Wielendek met PDU - Perronbeveiliging met aangedreven rol | Cargo Professional Suite (TMS) met Cargo Control en Cargo Direct Modules: - Airside Management - ULD Control System - Terminal AWB Control |

Handmatige en operatorgestuurde systemen

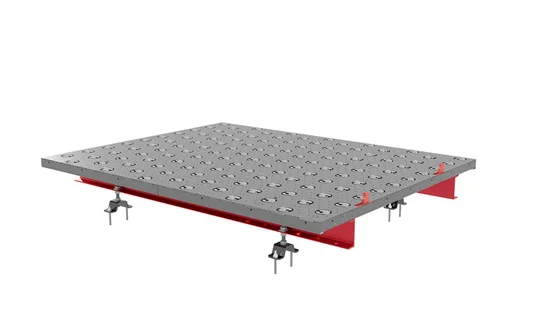

Handmatige verwerking biedt maximale flexibiliteit en dient als een betrouwbare basisoplossing. ULD's worden verplaatst op steunpallets en afgehandeld op gedefinieerde interfaces met handmatig bediende apparatuur. De functies omvatten de interface tussen terminal en platform en handmatige overdracht van en naar dollies.

Typische apparatuur | Software-onderdelen |

|---|---|

| - Castor Deck - Ball Deck - Cargo Pallet Mover & ULD Support Pallet - FlexLoader - Truck Dock | --- |

Verwante producten

Ontdek apparatuur voor ULD-handling

Ontdek gerelateerde producten die elke stap van ULD-afhandeling in uw terminal ondersteunen. Van acceptatie tot opslag en verdere overslag, deze oplossingen zorgen voor efficiëntie, veiligheid en een soepele integratie in uw goederenstroom.

Van landzijde naar luchtzijde - Ontdek de processen

Navigeer door de belangrijkste stappen van luchtvrachtafhandeling en ontdek hoe onze oplossingen elk proces ondersteunen.

Plannen of upgraden van je airside proces?

Onze experts staan klaar om te helpen.

Veelgestelde vragen (FAQ)

De luchtzijdige interface is de operationele link tussen de terminal en het platform, waar ULD's worden overgebracht naar of ontvangen van vliegtuigen via dolly docks.

Uitgaande ULD's worden toegewezen aan hun vluchten en in de juiste volgorde naar het platform gebracht, zodat de afhandelingstermijnen worden nageleefd. Wanneer er een Terminal Management Systeem (TMS) aanwezig is, wordt de registratie en matching van ULD's automatisch afgehandeld, zodat handmatig scannen niet nodig is.

Afhankelijk van de proceslogica worden ze naar uitvalwerkstations, bufferzones of opslag geleid. Als er een Terminal Management Systeem (TMS) aanwezig is, gebeurt de registratie automatisch zonder dat handmatig scannen nodig is.

Ja. Halfautomatische en volledig geautomatiseerde systemen beheren ULD-identificatie, positionering, volgorde en timing van overdracht met minimale handmatige input.

Absoluut. Vluchtinformatie, tijdsloten en ULD-planningsgegevens zijn geïntegreerd in het Terminal Management Systeem om een tijdige en nauwkeurige overdracht te garanderen.

Elke ULD wordt gescand en geregistreerd bij overdracht, waardoor volledige traceerbaarheid voor uitgaande en inkomende stromen binnen het TMS mogelijk is.

Gangbare apparatuur omvat dolly docks, aangedreven roldekken, ULD-scanners, contoursensoren en softwaregebaseerde vluchtbehandelingslogica.

Geïntegreerde software past de volgorde en toewijzing van ULD's dynamisch aan op basis van real-time vluchtupdates en feedback van het platform.

Ja. Alle systemen van Lödige voldoen aan de AHM- en ULD-handlingnormen van IATA om compatibiliteit en veiligheid te garanderen.

Ja. Lödige biedt oplossingen op maat voor nieuwe en bestaande terminals, inclusief modulaire upgrades en gefaseerde automatiseringsconcepten.